Tantalum Pentoxide

Ta2O5 is used to make capacitors in automotive electronics, cell phones, and pagers, electronic circuitry; thin-film components; and high-speed tools. In the 1990s, there was a very strong interest to do research on tantalum oxide as a high-k dielectric for DRAM capacitor applications. For example, Elpida Memory (a Japanese company making DRAM) has put in a strong effort to improve ultrathin tantalum oxide films for DRAM applications. Subsequently in the 2000s, this strong interest has dropped very significantly. There is still some interest to use it in MIM capacitors for RF CMOS integrated circuits.

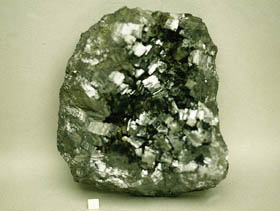

Niobium (Columbium)

Niobium and columbium are synonymous names for the chemical element with atomic number 41; columbium was the name given in 1801, and niobium (Nb) was the name officially designated by the International Union of Pure and Applied Chemistry in 1950. Niobium in the form of ferro niobium is used worldwide, mostly as an alloying element in steels and in super alloys. Appreciable amounts of niobium in the form of high-purity ferro niobium and nickel niobium are used in applications as jet engine components, and heat-resisting and combustion equipment.

Tin (Cassiterite)

Tin is the 49th most abundant element in the Earth‘s crust,This silvery, malleable poor metal is not easily oxidized in air and is used to coat other metals to prevent corrosion. The first alloyused in large scale since 3000 BC was bronze, an alloy of tin and copper. After 600 BC pure metallic tin was produced.Tin resists corrosion from distilled, sea and soft tap water, but can be attacked by strong acids, alkalis, and acid salts. Tin can be highly polished and is used as a protective coat for other metals in order to prevent corrosion or other chemical action

Tungsten (Wolframite)

Tungsten is found in the minerals wolframite, Tungsten is mainly used in the production of hard materials based on tungsten carbide, one of the hardest carbides, with a melting point of 2770 °C. WC is an efficient electrical conductor, but W2C is less so. WC is used to make wear-resistant abrasives and cutters and knives for drills, circular saws, milling and turning tools used by the metalworking, woodworking, mining, petroleum and construction industries and accounts for about 60% of current tungsten consumption.